Industrial Cosmetic Equipment: The Engine Behind Global Beauty Brands, Powered by Ailusimixer

The world of cosmetics is one of artistry and allure, but its foundation is built upon the robust, precise, and unyielding world of industrial manufacturing. Behind the vibrant palette of lipsticks, the luxurious textures of creams, and the potent efficacy of serums lies a complex ecosystem of machinery designed for scale, consistency, and uncompromising quality. This is the realm of industrial cosmetic equipment—the critical infrastructure that transforms raw ingredients into the products that grace shelves worldwide. For brands seeking a partner in this high-stakes environment, Ailusimixer has emerged as a beacon of innovation, reliability, and tailored engineering, providing the industrial muscle that empowers beauty brands to grow.

The Demands of Industrial-Scale Cosmetic Production

Transitioning from small-batch creation to industrial-scale manufacturing presents a unique set of challenges. It’s no longer just about making a great product once; it’s about replicating that perfection across thousands, or even millions, of units, batch after batch. Key industrial demands include:

Ailusimixer understands these pressures intimately. Their entire design and manufacturing philosophy is oriented toward meeting and exceeding the rigorous demands of the industrial landscape.

Ailusimixer: Engineering Industrial-Grade Solutions

Ailusimixer stands apart in the industrial cosmetic equipment sector by focusing on holistic system solutions rather than just selling machines. Their approach is to become an extension of a brand’s production team, providing the technology and expertise needed to build a foundation for scalable success.

1. Core Equipment Built for Industrial Duty:

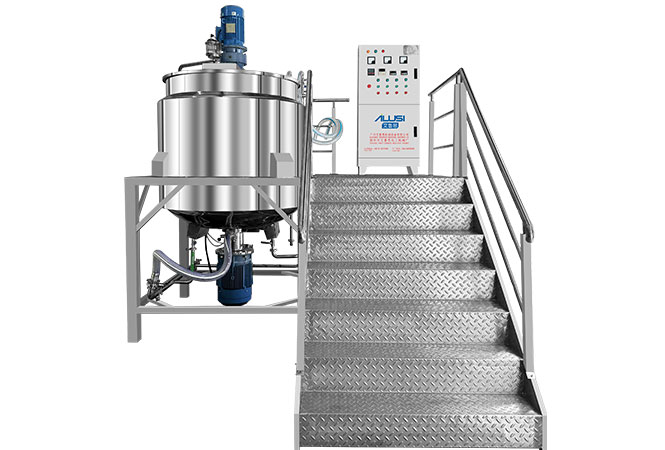

At the heart of any production line are the primary processing units. Ailusimixer’s flagship Industrial Vacuum Emulsifiers and High-Shear Homogenizers are engineered for heavy-duty cycles. Constructed from high-grade stainless steel with precision-machined rotors and stators, these systems deliver powerful, uniform shear to create exceptionally stable emulsions. Their vacuum capabilities are crucial for industrial batches, removing entrapped air to extend shelf life, improve product integrity, and ensure a flawless final texture in creams, lotions, and complex serums.

2. Sanitary Design as a Standard:

For Ailusimixer, hygiene is not an option; it is engineered into every weld, valve, and surface finish. Their equipment features polished, crevice-free interiors, sanitary fittings, and often incorporates Clean-In-Place (CIP) and Sterilize-In-Place (SIP) systems. This design minimizes cross-contamination risks, reduces cleaning time between batches, and ensures compliance with the most stringent global regulatory standards—a non-negotiable requirement for industrial producers.

3. Automation and Control for Precision and Repeatability:

Industrial scale demands industrial control. Ailusimixer integrates advanced PLC (Programmable Logic Controller) systems with user-friendly HMI (Human-Machine Interface) touchscreens. This allows operators to save, replicate, and precisely execute recipes for different products. Parameters like temperature, shear speed, vacuum level, and mixing time are meticulously controlled and logged, guaranteeing that the ten-thousandth batch is as perfect as the first. This level of automation reduces human error, enhances traceability, and optimizes overall equipment effectiveness (OEE).

4. Customization and Line Integration:

Recognizing that no two production facilities are identical, Ailusimixer excels at providing customized solutions. They work with clients to design integrated production lines that may include raw material feeding systems, multi-stage mixing vessels, heating and cooling loops, and product transfer systems. This focus on creating a cohesive workflow maximizes throughput, minimizes product handling, and creates a lean, efficient manufacturing environment.

The Ailusimixer Partnership: Beyond the Machinery

Choosing Ailusimixer means investing in a partnership. Their service begins with a deep dive into the client’s production goals, formulation challenges, and capacity needs. Their engineering team provides expert layout and flow consultation. Furthermore, comprehensive training and responsive after-sales support ensure that clients can maintain peak operational performance, maximizing their uptime and protecting their production investment for years to come.

Conclusion: Powering the Future of Beauty Manufacturing

In the competitive and fast-paced world of cosmetic manufacturing, the choice of industrial cosmetic equipment is a strategic decision that dictates a brand’s capacity for growth, quality assurance, and market responsiveness. Ailusimixer has positioned itself as a pivotal force in this sector by delivering more than just machines—it delivers engineered systems built on the pillars of durability, precision, hygiene, and intelligent automation.

For brands looking to solidify their industrial capabilities, expand their production reach, or build a new facility from the ground up, Ailusimixer provides the reliable, high-performance foundation necessary for success. By partnering with a supplier that masters the science of scale, cosmetic companies can confidently focus on creativity and brand building, knowing their production engine is powered by Ailusimixer’s unwavering excellence.