Toothpaste Manufacturing Machine: Engineering Precision with Ailusimixer

Toothpaste Manufacturing Machine

In the realm of daily essentials, toothpaste stands as a cornerstone of personal health and hygiene. Behind every tube that promises whitening, sensitivity relief, or natural care lies a complex, precise, and highly regulated manufacturing process. The transformation of raw powders, gels, abrasives, and active ingredients into a consistent, safe, and effective paste demands more than just a recipe—it requires industrial-grade precision and reliability. This is where the engineering excellence of Ailusimixer comes into play, providing advanced toothpaste manufacturing machine solutions that empower brands worldwide to produce with confidence, scale with efficiency, and innovate without limits.

The creation of toothpaste is a delicate balance of chemistry and mechanical engineering. Ingredients ranging from abrasives like silica and calcium carbonate to humectants, binders, flavoring oils, and critical active agents such as fluoride must be combined in exact proportions. They must then be mixed into an impeccably smooth, homogeneous paste with precise viscosity, devoid of air bubbles or graininess, and consistently filled into tubes or other packaging without separation. Any deviation can affect product efficacy, shelf stability, and ultimately, consumer trust. Ailusimixer designs its machinery to master every step of this sensitive process, ensuring flawless execution from raw material to sealed product.

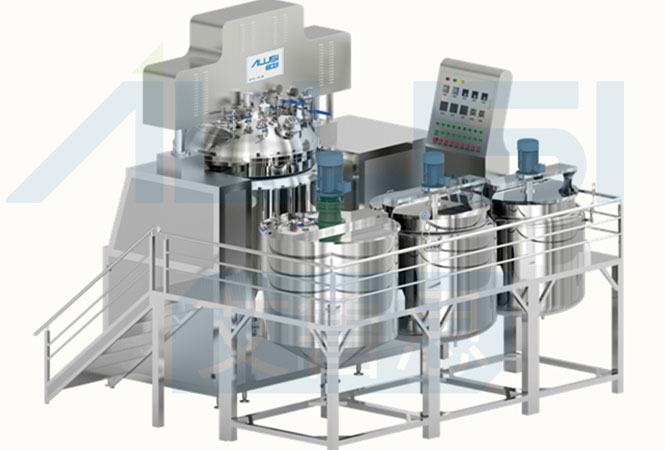

At the core of any toothpaste production line is the mixing system, and this is a primary area of Ailusimixer expertise. Our high-shear vacuum mixers are engineered to tackle the specific challenges of toothpaste formulations. Mixing under a vacuum is crucial; it removes entrained air during the compounding process, preventing the finished paste from becoming aerated. Aeration can lead to unsightly voids in the tube, inconsistent dispensing, and potential degradation of active ingredients. Ailusimixer mixers deliver powerful, controlled shear forces that thoroughly disperse powdered abrasives and other solids into the liquid base, creating a supremely smooth and uniform gel paste. This is vital for both product quality and sensory appeal—no consumer wants a gritty or separating toothpaste.

Furthermore, the order of addition and temperature control during mixing are paramount. Ailusimixer systems feature jacketed vessels with precise thermal control, allowing operators to manage the exothermic reactions that can occur during mixing and maintain the optimal temperature for ingredient stability. Our programmable logic controller (PLC) systems enable reproducible, automated batch processes, ensuring that every production run matches the last, guaranteeing the brand’s quality promise is embedded in every single tube.

Once the perfect paste is achieved, the challenge shifts to packaging. The toothpaste filling machine segment of the Ailusimixer line is a marvel of accuracy and cleanliness. Filling viscous, non-Newtonian fluids like toothpaste into aluminum, laminate, or plastic tubes requires specialized piston filling technology. Our fillers are designed to handle a wide range of viscosities and formulations, from thick traditional pastes to newer transparent gels, without dripping or smearing. The filling nozzles precisely descend into the tube, filling from the bottom up to prevent air inclusion, which is critical for maintaining the correct volume and product integrity. Coupled with automatic tube capping (screw-on or snap-on) and coding, this stage is fully automatable, maximizing throughput and minimizing human contact with the product.

Hygiene and compliance are non-negotiable in the production of personal care products that border on the pharmaceutical. Ailusimixer builds every toothpaste manufacturing machine with Grade 304 or 316 stainless steel, featuring polished, crevice-free surfaces that meet the highest Good Manufacturing Practice (GMP) standards. Our designs emphasize cleanability and prevent cross-contamination, which is especially important for manufacturers producing multiple formulations or varieties on the same line. This commitment to sanitary design protects your product, your brand reputation, and ultimately, the end-user.

The modern toothpaste market is dynamic, driven by consumer demand for innovation. From charcoal-based formulas and hydroxyapatite for enamel repair to all-natural and fluoride-free options, manufacturers need agility. Ailusimixer machinery provides this vital flexibility. Our production lines are modular and scalable. A brand can start with a semi-automatic setup for pilot batches and new product development and seamlessly scale up to a high-speed, fully automated line as demand grows. Quick-change parts and easy-to-adjust parameters allow for rapid switching between different paste types, colors, and tube sizes, dramatically reducing downtime and enabling efficient small-batch production runs.

Choosing Ailusimixer is not merely a transaction; it is the beginning of a technical partnership. We work closely with our clients to understand their specific formulation characteristics, output targets, and facility constraints. Our engineers provide comprehensive support from factory acceptance testing and installation to operator training and after-sales service. This collaborative approach ensures that the integration of an Ailusimixer toothpaste manufacturing machine into your facility is smooth and that the equipment delivers optimal performance throughout its long operational life.

In conclusion, the machinery behind toothpaste production is the silent guardian of oral health worldwide. It is the guarantee of consistent flavor, effective fluoride delivery, perfect texture, and reliable packaging. Ailusimixer is proud to be at the forefront of this essential technology, providing robust, intelligent, and hygienic manufacturing solutions. We empower brands—from emerging startups to established global leaders—to manufacture excellence, innovate with freedom, and build trust with every tube they produce.

For manufacturers ready to elevate their production standards, ensure uncompromising quality, and embrace the future of oral care, the path is clear. Partner with Ailusimixer, where advanced engineering meets dedicated collaboration, to build a foundation for success that is as solid and reliable as the machinery we create.