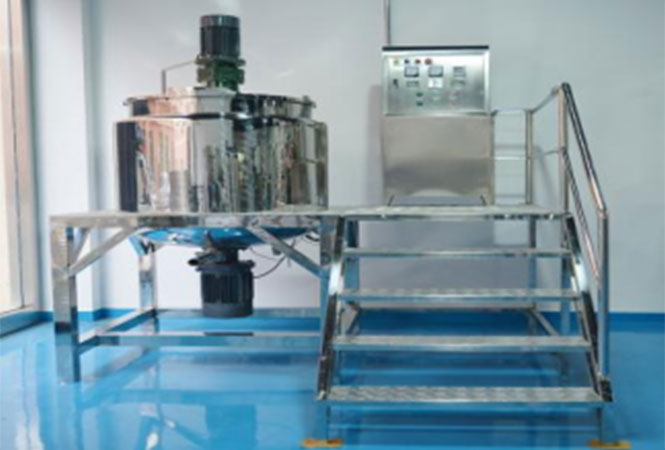

vacuum homogenizing emulsifier

In the precise world of industrial manufacturing, the creation of a stable, flawless emulsion is a fundamental challenge that spans across industries. From the luxurious consistency of a high-end cosmetic cream to the critical dosage uniformity of a pharmaceutical ointment, the underlying technology that makes such products possible is often the same: the vacuum homogenizing emulsifier. This sophisticated machine is the cornerstone of modern production, capable of transforming separate ingredients into a perfectly homogenous, stable, and superior end-product. For manufacturers who refuse to compromise on quality, the Ailusimixer brand has become a benchmark for excellence, engineering vacuum homogenizing emulsifiers that combine robust power with meticulous precision.

This article explores the critical science behind this technology and details the engineering principles that make Ailusimixer a preferred choice for leading producers worldwide.

Deconstructing the Process: The Triad of Perfect Emulsification

A vacuum homogenizing emulsifier is not a simple mixer; it is an integrated system designed to overcome the inherent instability of emulsions. Its effectiveness lies in the synchronized operation of three core components, each addressing a specific challenge.

The Ailusimixer Advantage: Engineering for Uncompromising Performance

While the principles of vacuum homogenization are universal, the execution defines the leader. Ailusimixer distinguishes itself through a commitment to durability, precision, and intelligent design that delivers tangible value on the production floor.

1. Robust Construction for Demanding Environments

Ailusimixer builds its vacuum homogenizing emulsifiers to last. All parts that contact the product are manufactured from high-grade 316L stainless steel, chosen for its exceptional corrosion resistance and compliance with stringent hygienic standards. The interior surfaces are often electropolished to a mirror finish, which minimizes adhesion and allows for rapid, thorough cleaning and sterilization. This focus on hygienic design prevents cross-contamination and ensures the integrity of every batch, which is non-negotiable in pharmaceutical and cosmetic applications.

2. Precision Thermal Control

Emulsion quality is highly sensitive to temperature. Many formulations require specific heating and cooling cycles to properly melt emulsifying waxes or to incorporate heat-sensitive actives without degradation. Ailusimixer systems feature a jacketed vessel that provides precise and responsive temperature control. Using water or thermal oil as a medium, the system can maintain an exact temperature profile throughout the entire process, which is crucial for achieving a perfect emulsion structure and ensuring batch-to-batch consistency.

3. Power and Versatility in Homogenization

The core of the machine—the homogenizer—is engineered for both power and flexibility. Ailusimixer utilizes high-torque motors and precision-balanced rotor-stator assemblies that can effortlessly handle a vast range of viscosities, from lightweight lotions to thick, paste-like creams and ointments. The ability to adjust the homogenizer’s speed allows operators to fine-tune the shear force for different product phases, ensuring optimal particle size reduction without damaging delicate structural components.

4. Intelligent Automation for Flawless Reproducibility

In modern manufacturing, consistency is synonymous with quality. Ailusimixer’s advanced models are equipped with user-friendly Programmable Logic Controller (PLC) systems. Through an intuitive touchscreen interface, operators can create, store, and execute complex recipes. This automation ensures that every critical parameter—from homogenizer speed and vacuum level to temperature ramps and mixing times—is controlled with precision. This eliminates human error and guarantees that a product manufactured today is identical to one produced six months from now, solidifying brand reputation.

Applications Across Industries

The versatility of the Ailusimixer vacuum homogenizing emulsifier makes it a vital asset in numerous sectors:

Conclusion: A Strategic Partnership in Quality

Selecting a vacuum homogenizing emulsifier is one of the most significant decisions a manufacturer can make, as it directly impacts product quality, operational efficiency, and brand integrity. Ailusimixer represents more than just machinery; it embodies a partnership in manufacturing excellence. By integrating powerful homogenization, a pristine vacuum environment, and intelligent control into a durable and hygienic platform, Ailusimixer provides the reliable technology needed to create superior, market-leading emulsions.

For any enterprise dedicated to achieving perfection in their products, investing in an Ailusimixer vacuum homogenizing emulsifier is not merely a purchase—it is a strategic commitment to quality, innovation, and long-term success.