Efficient perfume manufacturing relies on the seamless coordination of mixing, filling, and packaging processes. Modern perfume machines are designed to simplify these operations while maintaining the integrity and consistency of every fragrance. Whether you’re producing a high-end signature scent or running large-scale production, choosing the right equipment is crucial.

A perfume mixing machine plays a foundational role in the perfume production process. It blends essential oils, alcohol, and other ingredients into a stable and homogenous solution. With advanced features like vacuum mixing, temperature control, and high-shear emulsification, these machines ensure that the fragrance compound is uniform and long-lasting. At Ailusi Mixer, these systems are built with sanitary stainless steel and are available in various capacities, making them suitable for both laboratory use and industrial-scale production.

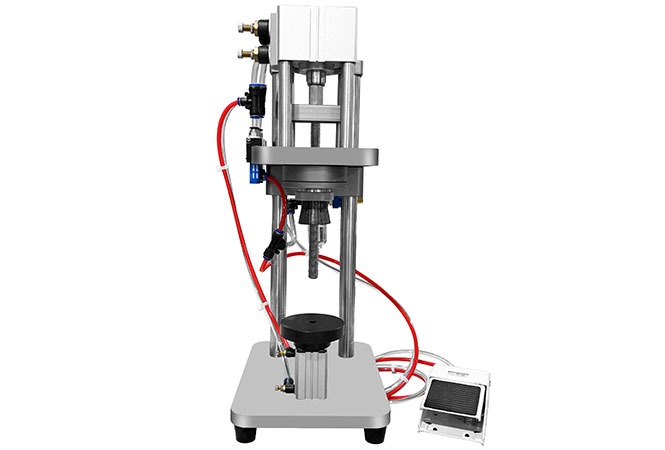

Once mixing is complete, the next stage is precise filling. An automatic perfume filling machine takes over this task with speed and accuracy. These machines eliminate manual errors and ensure consistent volume per bottle, which is essential for both quality control and customer satisfaction. Automatic systems typically support glass or plastic bottles of different shapes and sizes and can be integrated with capping and labeling equipment for a full production line setup.

What sets advanced perfume machines apart is their automation and adaptability. Many systems come with touch-screen PLC controls, recipe storage, and intelligent filling mechanisms. This allows operators to switch between products with minimal downtime, enhancing overall productivity. For manufacturers dealing with multiple fragrance lines, this flexibility is a major advantage.

Another key consideration is hygiene. Both perfume mixing machines and filling machines are constructed with materials that meet GMP standards and are easy to clean. CIP (clean-in-place) systems are commonly integrated to reduce manual cleaning and prevent cross-contamination between batches.

Cost-efficiency is also a factor. While upfront investment in high-end automatic perfume filling machines may be significant, the return on investment comes through reduced labor, higher output, and minimal waste. At Ailusi Mixer, machines are built with longevity in mind and are customizable based on your volume and bottle type requirements.

From small businesses to established fragrance manufacturers, the right perfume equipment can scale production without compromising quality. Whether you’re looking for a standalone perfume mixing machine or a fully automatic perfume filling machine line, Ailusi Mixer offers tailored solutions that align with modern production standards.

Visit AilusiMixer.com to explore the full range of perfume machines and discover how the right technology can elevate your fragrance production process.